“I confess that I am in love with wood. Wood to me has personality. It talks to me. It is grained in its consistency, its hardness or softness, in its music. The vibrating wood, just a plain reed vibrating in the wind, is music. And if you put it into a properly designed soundbox, as Chris said, wrap wood around the sound, you get a guitar tone. Tone is the key word in my opinion. There is a tendency to over emphasize the appearance, the figure of the wood rather than the tone, and they don’t always go together.”

— C.F. Martin III

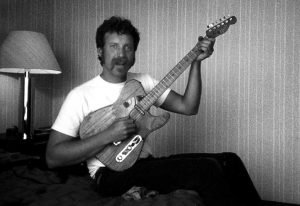

Dick Boak nearly lost his eyesight at the age of six and ever since, has concerned himself with visual details.Unable to surpass his older brothers in the sports arena, he focused instead on drawing, woodworking, writing and music. In his teens, he self-published two booklets of poetry, immersed himself in technical drafting, and began to experiment with musical instrument design and construction. In the late 1960s, Dick headed off to college and soon joined the counterculture. Fascinated with the architecture of Buckminster Fuller, he began designing and building geodesic domes. Upon crossing the theoretical threshold into art, he abandoned academics in favor of a daily commitment to creativity. After locking himself up for three days in his notorious Kafka-esque living sculpture The Cage, he fled to the outskirts of society to pursue his passion for illustration, whole earth structures and the copious keeping of journals.His wanderings took him to Vermont where he worked a series of disastrous jobs in support of his bohemian lifestyle. Eventually, he departed for California with a band of likeminded hippies in search of the utopian dream. Landing at Lou Gottlieb’s infamous Morningstar Ranch commune, he constructed many handhewn dwellings and domes and entered his most prolific years as a conceptual illustrator. Returning to the East Coast, he became an art teacher, lathe turner, performing musician and luthier. In 1973, he discovered C. F. Martin & Co. and was soon hired as a design draftsman. Since then and for the past 32 years, he has held many diverse and creative positions there, leading to the formation of Martin’s Artist Relations Department and the conception of more than one hundred and forty signature guitar collaborations with the top musical talents of our time. His acclaimed book Martin Guitar Masterpieces relays the stories of those collaborations. For 17 years, he lived in his converted “Church Of Art,” an active studio for art, woodworking and live music.

Currently living in Nazareth, Pennsylvania with his wife Susan and their two daughters Emily and Grace, he continues to build his legacy with The Martin Guitar Company, finding occasional time to further his art and music, and work on the publication of his more personal book Dot To Dot – The Creative, Comical & Covert Adventures of Dick Boak.

The C.F. Martin Company continues to set the standard for American-made acoustic instruments, and throughout the company’s long history wood has remained its core resource, essential to the enduring quality and tone of Martin guitars. Pre-war Martin instruments command the highest prices today among all vintage guitars – acoustic or electric, and at the time these highly-prized guitars were made, wood such as Adirondack spruce, Honduras mahogany, ebony and Brazilian rosewood was plentiful. Despite the market forces of supply and demand, increased competition among manufacturers to acquire premium wood, rising prices and environmental regulation, Martin has succeeded in maintaining the quality of its instruments while recreating many of its most desirable models from the past in faithful and meticulous detail. Clearly, the C.F. Martin company is staffed with skilled craftsmen who are keenly familiar with the company’s tradition and art of guitar building, but as in 1939, wood remains the heart and soul of the acoustic guitar. How has Martin managed to maintain their high standards in an increasingly competitive and regulated global economy? We asked Dick Boak and his associate, wood buyer Linda DavisWallen to describe how the acquisition of wood suitable for guitar making has evolved and how Martin has evolved with those changes:

TQR: During the pre-war ‘golden era’ of the company’s history it is widely assumed that the wood species used by Martin were plentiful – literally at the factory’s doorstep in some cases, and relatively cheap. Is this scenario accurate? Was there a deliberate strategy to acquire and store wood for use far into the future at Martin?

I must say that while the traditional materials used on Martin guitar were “available,” they were by no means plentiful or cheap. Rosewood, ebony, mahogany and even spruce were, like they are today, premium materials. Limited logs would arrive at the varied sawmills and processing facilities along the Hudson River. Marshall was one of the primary mills. Frank Henry Martin or C. F. Martin III would travel to the mill to look at the logs, select one or two and give very specific instructions as to how the log should be quartersawn and to what thickness. This was done on a large circular saw that left subtle saw blade burn in the wood, especially the very dense rosewood. Sometimes, multiple mills were necessary for cutting or resawing the wood into flitches or specific fingerboard and bridge blanks. While the prices would be low compared to price and availability today, the cost would still be considered quite high in comparison to other available woods.

TQR: Since production was much lower than it is today, we would assume that there were few sawmills operating in the early days that were capable of or willing to produce the type of kiln-dried boards that Martin required for production. Did Martin buy green logs for the most part that were then cut into suitable boards and dried and stored on the premises?

In 1985, I invited C. F. Martin III (age 91) to speak at a guitar making symposium that I was putting on. He accepted and his talk was wonderful and quite revealing. I have included a full transcript, but offer a pertinent portion of his remarks concerning wood and wood cutting as follows…

C. Frederick Martin III

“So, we look for wood. I was brought up very early. One of my first journeys away from Nazareth was a trip with my father to New York City, it must have been about 1903 or 1904 to visit the lumber yards. In later years I made many, many trips. We could go in one day from Easton by railroad to New York and go down to the East River, and there were three lumber yards along the East River between 6th and 10th Street where the East River Drive is now, and there we had a choice of logs – big logs. The logs for a guitar back when you quarter saw it and you want 7 1/2 or 8 inches, half of the back, has to be at least 18, preferably more than 20 inches in diameter. We couldn’t use small logs except for fingerboards. We had to have big logs. Then nearby on the East River in New York was the Molger Sawmill and the Hammond Afer Sawmill and the Marshall Mill, and I would have the logs I selected, usually only one or two, delivered to this sawmill and then I would go there and talk to the sawyer to make sure he understood how we wanted that log cut and the exact thickness – that it must be exact and we got a close relationship with our wood sawyers, producers, the people who made the basic materials. And I need not tell you people how important that it is that the thickness of the wood be exactly right. When you saw it, of course you leave a little extra wood to take off for the sanding machine. But, not too much because the wood is expensive. Even in those days, 10 or 12 cents per pound was a fairly good high price for rosewood. Now it’s several dollars. It’s expensive wood, and of course it was Brazil rosewood.

Now we don’t have Brazil rosewood any more; it’s very hard to get. The source has been cut off by embargoes by the Brazil government on people that come down there and saw the wood in Brazil. So, we can’t get the logs. So we turn to India. Rosewood from India is a somewhat different botanical species, but it is very similar in its tone properties and has been used for many years in Germany and other countries. So we turn to India for wood, and we got very large logs. Their logs are larger than the Brazil logs, and they cut beautifully. They don’t have the same color or the same grain as Brazil, but I do believe that the tone when the wood is properly sawn and treated is as good a Brazil rosewood. Then after that we decided to invest in a sawmill, our own sawmill, to saw these logs, and we bought expensive machinery in Europe to set up a new mill aside of our new guitar plant and proceeded to buy logs and saw them ourselves. And in three years the India government put an embargo on rosewood logs. So, we have to get either cants (small squares) or have it sawn over there. We still are getting the wood, and we had been able to get a little Brazil rosewood, but it is extremely scarce and right now we don’t know where we can get any more. So if any of you got some of these Brazil rosewood guitars, we made about 200 of them in the last three years, you have a rare item. In my opinion, guitar tone and figured wood do not go well together. In order to make a piece of wood either the sounding board spruce or the back rosewood or mahogany, you need vibrating qualities, and this calls for quarter-sawn, straight grain wood with a minimum figure. It vibrates better, I think, and I believe this is quite true. If it is straight and plain, you don’t want any knots, of course, we take those out. The treatment of wood is a fascinating thing.”

TQR: Did Martin’s wood buyers ever actually walk the woods and select specific trees?

No, this would have been very impractical, though it is quite possible that members of the Martin family may have traveled up to the Adirondack mountains in upstate New York to source red spruce.

TQR: What are the key considerations in assuring that the wood used to assemble guitars remains stable? We would assume that moisture content and grain structure are very important…

Wood must be dried carefully and correctly. Rosewood typically arrives wrapped in burlap in cut bookmatches quite wet with waxed ends. Using a moisture meter, we can determine the moisture content. Incoming wood is often 30% moisture content – sometimes higher. The sets need to be put up on sticks in a stable and well ventilated environment to season them down to about 12-15% so that they can go safely into our wet bulb kiln. The kiln is a slow process that brings the moisture down to about 7-8%, then the wood comes out and seasons again on sticks in our highly controlled acclimating room. We want the wood at about 8% before we use it. This can take some time! You certainly don’t want to build guitars with wood that is not very carefully dried, as it is a very large investment and incorrectly seasoned wood is at risk of cracking. In general, wood that is quartersawn is the most stable. We go to great lengths to try to secure straight grained quartered sets, but of course this is dependent upon the diameter of the tree and the skills of the sawyer. While we always prefer quartersawing, many of the woods we use are only available these days in off quarter form. In those cases we try to put the straight grain at the joined center seam of the top or back – keeping the wilder grain toward the outside edges of the instrument. Customers love dramatic and wild grain. Frankly, we find that attractive too, but the paradox is that ideal scenario for stability and tone calls for straight boring grained tonewoods, devoid of figure.

TQR: While certain structural design features of various models of Martin guitars have been documented as having been changed from the pre-war era through the ‘40s, ‘50s, ‘60s, it doesn’t appear that Martin’s use of Brazilian rosewood, Adirondack and Sitka spruce, Honduras mahogany and ebony during this period were affected by changing market conditions, availability or price. True?

We can assume that Martin always tried to work ahead (like we still do today) to secure a supply of woods well in advance of when the wood is actually needed for assembly. That way, there is plenty of time for seasoning. I suppose there is never too much time for this. After the Adirondack region became an immense National Park, most all of the logging in that area ceased, so gradually, as the 1940s came to a close new sources of spruce were sought. Sitka spruce from the Pacific Northwest, often quarter cut for aircrafts because of its strength to weight ratio, proved to be a good choice. In addition, alpine spruce from Germany and Italy was secured and utilized, mostly on higher priced models.

While there doesn’t seem to have been any serious interruption in securing genuine mahogany (not necessarily from Honduras), rosewood, or ebony, the bigger issue during war years was the steel T-bar used as a neck reinforcement. For a short time, the T-bar was replaced with ebony. And by the way, graphite was very valuable in the war effort, and pencils were considered precious – always sharpened until they were a mere stub. Even then, C. F. Martin III distributed thin copper tubes into which pencil stubs could be inserted to fully utilize every last bit of graphite.

TQR: Wood varies in terms of density/weight and grain structure, and different boards cut from the same tree can be quite different in this regard. Building guitars to Martin’s standards doesn’t seem to be an accidental process in which there is much guess work, yet you are still dealing with a variable product of nature… Aside from merely buying the type of wood required, how do you evaluate the actual wood you choose to buy to insure a consistent outcome? In other words, what features are you looking for and what do you want to avoid?

Indeed, every piece of wood has its own character. And every species adds tonal flavor to an instrument. We build guitars to exacting dimensions that walk the very fine line between strength and tone. It is true that if you were to weigh a dozen of our guitars of the same model, their weight will vary ever so slightly. If you were to take those same dozen guitars and evaluate their tone, they would be remarkably consistent, but undoubtedly, one or two would have a stronger bass, one or two a brighter treble, with the rest falling closely in between. I feel that heavier woods (like rosewood) will accentuate the bass resonance, while lighter woods (like mahogany) tend to add an airy clear treble to the sound. I think the same generalization might be made with small weight differences with a given model.

TQR: The late ‘60s and ‘70s produced some obvious changes as the 3-piece rosewood back was introduced, and the use of Brazilian was discontinued in favor of Indian rosewood. We have read articles from that time period describing how access to Brazilian rosewood didn’t really cease, but that the government required the logs to be milled in Brazil, and it was the unacceptable nature of that millwork that ended the use of Brazilian rosewood for Martin. Do we have this right?

Basically, you have it right. There is a story for Brazilian as well as East Indian rosewood. In late 1969 (and early 1970) Martin made the transition from the use of Brazilian to East Indian rosewood. Due to intense over-harvesting (primarily by the veneer industry), Brazil had placed an embargo on the export of Brazilian rosewood logs and prices were rising accordingly. The intent was to keep jobs and value in Brazil. Martin no longer had the ability to oversee the cutting of the logs, and turned to India where the prices, the availability and the quality were more attractive to Martin. At the time, there was little distinction between or knowledge about the different species of rosewood. Soon after the switch to East Indian rosewood, Martin initiated construction of a precision sawmill to cut mahogany and rosewood logs, but within 5 years of the sawmill’s completion, the Indian government suspended log shipments. Like Brazil, they chose instead to require that all cutting of wood be done within India. Martin continues to buy processed East Indian rosewood backs, sides, fingerboards and bridges – all cut to slightly oversize dimension in India. The introduction of the D-35 with its 3-piece back was certainly practical, but it was also an attractive visual design. It enabled otherwise rejected wood from two piece backs to be trimmed to the smaller 3-piece back components.

TQR: We have also read an account of a program that Martin developed in the mid ‘70s to acquire supplies of East Indian rosewood through a wholly owned subsidiary called The Sawmill Inc.. Don Thompson, director of research for Martin and head of the Sawmill explained in a Guitar Player interview that the only way Martin could maintain quality was to enter the wood importing business.

The Sawmill imported three grades of rosewood – low, middle and “C.F. Martin,” and they would sell rosewood to anyone who wanted it. How long did this program last, and has a similar strategy survived today?

I suppose the basic story is correct. Don Thompson, Director of R & D for Martin, built “The Sawmill” at great expense to cut logs, but shortly after its completion, Martin could no longer acquire logs of the woods that Martin needed. So, The Sawmill began to import logs and lumber of other exotic wood species for resale to the architectural millwork and high end woodworking markets. While Martin’s specification for the varied tonewoods is more stringent than most all other makers, I don’t recall that we ordered lower quality for resale, but often we did sell rosewood guitar sets that we deemed, after being inspected, to be of lesser quality than Martin desired. Many independent luthiers and some larger instrument making companies were Sawmill customers for these second quality sets.

TQR: Fast forward to the present… You are building more instruments and more varied models of guitars today than ever, while the guitar manufacturing industry had grown substantially both here and abroad. The amount of wood consumed annually for guitar building worldwide must be staggering… How has Martin positioned itself to maintain its high standards for the wood it acquires, and what is the outlook for the future?

Compared to other industries (plywood, construction, furniture) that use wood, I suspect that the guitar industry is a small fraction of the total, but yes, business is good and Martin is making a lot of guitars. With regulations such as CITES and The Lacey Act, compliance requires a great deal of integrity, attention and paperwork. The gradual depletion of the traditional tonewoods will require that alternatives be identified, utilized and accepted in the marketplace. That evolution is well underway, and while there will most likely always be a market for vintage guitars and the traditional woods, Martin is committed to the increased use of sustainable, responsibly harvested and certified woods. We’ve been in business for an unprecedented 181 years and we fully expect to be around for many, many decades to come.

C.F. Martin III Talk Given At ASIA Symposium 1985

After being introduced to the audience by Association Of Stringed Instrument Artisans (A.S.I.A.) Executive Director, Dick Boak, the elderly Mr. Martin steps slowly up to the podium, assisted with his cane and begins:

“I can walk upright, you know. Perhaps some of you have been or are now teachers, and maybe sometime you had the experience or will have of having your pupil do better than you do, and that’s the way I feel right now. Chris has done very well. I congratulate him on his talk. I brought this cane along because in the first place I need it. I fell and hurt my back last year, and Dick Boak recognized my need and he made me this cane. It is made of Indian rosewood with the Martin fingerboard position mark inlaid. That’s my great helper, and I’m very thankful to Dick Boak for it. I’ll lay it down –-very respectfully.

Let me set one thing straight. This is not a lecture. It’s billed as a lecture, I believe, but as a lecturer I never felt I was much of a success. I would like to talk about two or three things. I would like to talk about music, but I won’t because I’m not a musician. I would like to talk about the Martin family because I do know a great deal about that, but that might be tiresome. So, I think I’ll talk about the product. The product is guitars. They are made of wood. In researching the word “lute,” I find that it comes from Arabic two words meaning “the wood.” If you have studied the history of musical instruments at all, you know how many instruments, especially wooden instruments, came out of the Near East, the Arabic world, including the guitar, by way of Africa and Spain. So, “wood” is the key word. I confess that I am in love with wood. Wood to me has personality. It talks to me. It is grained in its consistency, its hardness or softness, in its music. The vibrating wood, just a plain reed vibrating in the wind, is music. And if you put it into a properly designed soundbox, as Chris said, wrap wood around the sound, you get a guitar tone.

Tone

Tone is the key word in my opinion. I was brought up that way, and I think Chris has caught the idea that tone is the one first outstanding essential. Maybe that’s just so common I shouldn’t even mention it. But, there is a tendency to over emphasize the appearance, the figure of the wood rather than the tone, and they don’t always go together. Tone wood as the Germans call it basically is straight grained, quarter sawn wood, and most of you probably know what quarter sawn is. That refers to the log and the radial cuts as opposed to flat sawn, and the difference in the vibrating qualities of the wood, especially in the sounding board of a guitar or a piano is considerable if it’s cut differently.

In my early days when all guitars including Martin guitars were strung with gut strings, silk centered basses and played with the fingers, I sometimes was asked to select guitars for particular customers. I learned to play the guitar a little; I’m certainly not an expert; I’m not a musician. I have short fingers like a mechanic, not the long fingers of a musician. But, I tried and had some little success, I think with it. We didn’t encourage it because tone is a subjective matter. If we have six guitars, two individuals might pick out two different guitars. They will not necessarily agree. So we didn’t encourage that. There are variations in guitars. There are bound to be because no two pieces of wood are exactly, precisely alike. They differ in hardness, they differ in the width of the grain, and the narrow grain which looks so nice isn’t always the best for tone. We like a medium, narrow, maybe 12 or 13 to the inch, with the tighter grain on the edge of the body and with the wider grain, they do differ in the center of the top. That, we think, is the best vibration. And then, of course, the importance is thickness. The bigger the guitar, the thicker the top has to be because of the strain of the strings. In the old days guitars made with gut strings and now with nylon had thinner tops, in fact thinner backs and sides too.

Steel Strings

Steel strings came, and we began using them in the early ‘20s and we found it necessary to add a little to the thickness of top and the back and we designed what is now called the belly bridge. The old bridges were straight on both edges, front and back, and heavy strings increased the tension naturally. This has changed now. People are using lighter strings, I believe, and we are going back to thinner wood, lighter bracing and the so-called scalloped bracing which was a feature of early Martin guitars that we abandoned about 1945 or 1946 when very heavy strings came into general use, and the bridge plate was increased in size too. Now we are reversing that. More people are using lighter strings, playing with the fingers, and we are going back to lighter bracing, thinner wood and more response to the lighter strings. The style of playing is the function here that we can’t control at all. We do try to keep our ears tuned to the marketplace to know what people are doing, what they are about to do if possible, forecast the future. It’s important to not only keep up but to keep ahead if possible. So we are constantly, and this is the whole history of the Martin Guitar Company – constantly developing and working on prototypes and modifications which may seem small in themselves like the scalloped braces, but they are important to tone. I’m very happy about this, getting back to lighter construction and thinner wood for lighter strings, but we brand the guitars that only medium or lighter strings should be used. This has always been a problem for guitarmakers because the marketplace is very wide, very varied, and is constantly changing. It is hard for us to make a guitar now and make sure that it will please everybody. You can’t do that; that’s impossible. You have to know what is wanted by the most people; you gauge your market. We were late to change to steel strings. We did in the early ‘20s; we started with one model strung with steel strings as an option and then several more models and finally steel strings were made standard about 1926 or 1927. Other guitarmakers had gone to steel strings long before that, but we made lighter guitars, thinner wood and they were intended for gut strings. Nylon strings of course came after World War II. You know the story of nylon strings. So, we used rosewood basically; all early Martin guitars before 1900 were made of rosewood, with some few exceptions. We have a page from an old sales book which mentions several other woods that were used for special orders apparently. Even then and to this day we are working with other woods as options in case we have to change some day, like the Brazil rosewood.

Fingerboards, all were ebony before 1900. Ebony from Africa, Gaboon ebony from Central West Africa was the preferred wood, the best, it’s all black, very hard and takes frets very well. Now that particular kind of ebony is hard to get. We have to get ebony from other areas in Africa, and it’s not always completely black. Sometimes there are brown streaks, which we stain and make it look all black, but it is true ebony. Its the same botanical species. There is a brown ebony grown in Brazil and some in Central America, but we have never used that.

Drying and Seasoning

We’ve used rosewood for fingerboards. Rosewood is a hard wood, not as hard as ebony, but hard enough to take frets well and to wear well. Seasoning wood is much talked about and the many ways to do it. When a tree is felled, there is sap in it and maybe 15, 16 percent moisture by weight. That moisture has to be expelled in some manner, as you all well know. Our method of doing it is to run it through a dryer, an electric kiln in our sawmill, and then rack it vertically in our air conditioned plant with air circulating all the time. In the old factory, and when I speak of old and new, the dividing line is 1964 when we moved from the plant on North Street in Nazareth to the new plant on Beil Avenue where we now have air conditioning and everything is on one floor and much easier to get around. I no longer have to climb three or four flights of steps a dozen times a day as I did for many years. There is no substitute for the time element in seasoning or drying wood. Really there is a difference between drying and seasoning. You can measure dryness with an instrument to a percentage of moisture. Seasoning is something that effects the texture of the wood so that in producing a sounding board for any musical instrument, it is important that it have some seasoning in addition to drying. So we like to keep wood for several years, and we like to rack it vertically. After it is well dried, we will grade it, match pairs, then rack it in vertical racks.

The Voice of the Tree

In the old factory, the North Street plant, these racks were at the ceiling. There was no air conditioning, but the heat rose from the radiators to the ceiling and there were openings in the floor above, the attic floor, to vent the heat; we got vertical circulation, and it was very effective and very inexpensive. Air conditioning costs a lot more, but you can control it. We could not control the natural seasoning or air drying. I like to think of the wood in the guitar as the voice of the tree. We had in our home on North Street, the Martin homestead, when I was growing up as a small boy, a spruce pine tree. Spruce you know is the standard wood for sounding boards. We had a spruce pine tree on the south side of the house. It stood there alone. It did very well; it grew much taller than the house, and at one point I think it was around 1835 or somewhere in there my father said we’ll take that tree down. It’s mature now, and it will make good guitar braces. It wasn’t wide enough for tops. Good guitar braces also have to be cut vertically on the quarter. So we took it down, cut it into logs, and when we opened it we found it wasn’t suitable at all for these braces because all the grain was wide, an eighth inch or more wide. Well, that’s too wide for a musical instrument, and the reason for it as I see it as father saw it was that the tree grew alone under ideal conditions and it grew too fast. Good close grain spruce grows on the north side of the mountain in a forest, not by itself. Maybe there’s a morale there. I won’t try to preach a sermon on it. That’s what I mean about wood. It does have personality. I love wood. My father loved wood, and I think all my ancestors did.

Dreadnoughts

The idea came from a dealer by the name of Harry Hunt who was manager of the string instrument department at the Oliver Ditson store here in New York on 34th Street. He was talking to my father –-I was in college at the time. He said how about a guitar with the shape they used to use in Spain with a wider waist and a little deeper body and a long body. Well, my father seemed to think it was an idea worth considering, so in his usual methodical manner, he proceeded to make a sample, a prototype, and submitted it, and Mr. Hunt thought that was pretty good. Can you make it in three sizes? Yes, he thought he could, and in the end we made for the Ditson Company three sizes of what is now the Dreadnought guitar. You know how big it is. The smaller size was called standard, the middle size was called concert, and for the large size Mr. Hunt suggested the name Dreadnought because it was in the news in those days, that was 1915-16-17 before World War I, Dreadnought was the name of the famous British battleship and this was the biggest guitar we had ever made, probably ever or probably ever been shown in the market. So, father accepted the name; he thought it had a unique sound to begin with and was very descriptive. The guitar didn’t take any prizes for good looks, it’s a homely guitar, very big with a very big tone and we made it only for the Ditson Company. They supplied the numbers for it. If you ever come across any of these, they were made for about ten years up until about ‘25 or ‘26, they are quite rare. They were numbered and branded with the Ditson stamp and the Martin stamp, and the numbers were number 1 for the smallest one in mahogany like style 18, number 111 for the middle size and number 1111 for the Dreadnought. They used those numbers, and the second style was the style we called 28 they called number 2, and then 22 for middle size and 222 for the large size, and we do not have any, have never seen, any old used guitars with those numbers. We very much would like to have one for our museum. We have one of the little ones which you may have seen. The number 3 was like our style 45 with pearl inlay, ebony fingerboard and the old fashioned position marks, and that was 333 and 333. Those were nine models, different sizes, three sizes and three styles, that were made only for the Ditson Company. The Ditson Company went out of business about 1926 or 1927 and did not claim any rights to the model, so it was ours. We offered it in our catalogue, but there was very little interest. Eventually we dropped the smaller sizes and offered only the larger size and it caught hold in the Southern Appalachians music market because of its deep bass, and then it went to town. We had a winner. We had originally, of course, had the sharp neck joined to the body at the twelfth fret and a slotted head. We changed that to 14 frets in the early ‘20s, and solid head which is now standard as you know. So that’s the evolution of the Dreadnought guitar. Now we are making vintage Dreadnoughts designed like the older ones with the old pearl inlays in the fingerboards and other features of the old models. That’s been the story; that’s only one model, and we have through the years made many different ideas in guitars, few of them finally got to market. In anything of that kind when you are experimenting and developing, it’s the exception that succeeds, but that doesn’t mean you shouldn’t try. So, we keep trying, even today. Right now we have recently developed what we call a jumbo model which is even larger than the Dreadnought and an M model which is wider but not as deep as the Dreadnought, and these have different tone characteristics. Tone is the one thing that remains constant through the whole history of our company, and in my opinion this is the basic element in all instrument construction.

Quality not Quantity

My father was a man of high principles. I’m afraid, I’m sorry to say he does not get the credit he should have for building up the business. It was his open mind that accepted that idea for the Dreadnought guitar. It was his open mind that accepted the idea for a longer neck. I was involved in that, but he was the main one. He was a classic student, never went to college, didn’t have that opportunity but studied Latin and Greek and history. When I was growing up, he would work all day in the shop making guitars at the bench, do the bookkeeping in the evening and read right before he went to bed. He read Gibbons Decline and Fall of the Roman Empire, through, and that’s a big book. He was a real student. As he developed these ideas, he never, well I shouldn’t say that, he did want as many guitars for as many people as possible. It wasn’t so much the quantity as it was the fact that he could put a good guitar in the hands of many people. In our early catalogues we emphasized and put up front the cheaper guitars which was contrary to the rules of advertising and marketing. You should put your high priced stuff up front and lower priced stuff in the back, right? Well, he didn’t do that. He wanted to make as many plain guitars as possible so that more people could use them because they were lower in price. Believe it or not, at one time we had a guitar that retailed at $25 but not for long. It got caught in the inflation after World War I, about 1919 and 1920. But, now we do as everybody else does, we put the D-45 up front and the plainer guitars in the back of the book. We try to give quality as I say rather than quantity and here’s an interesting personal note, very personal. When I was growing up in my bedroom was a wooden plaque, about 2 feet by 15 inches, with fancy edges, and on it were in rosewood letters glued onto this light wood maple back, the words “Non Multa Sed Multum” Latin words meaning “not many, but much.” In plain English, quality rather than quantity. That was his philosophy, and I consider myself very fortunate in having him as a teacher and mentor as Chris said. I had a younger brother who handled sales for us. He also went to college with me, and unfortunately he died in 1927. It was just the two of us; and after that I took his place in visiting the music dealers. By that time the ukulele had become the big business; we doubled our factory, and it really was a very nice, profitable business. And I got into sales, and then came the Depression in the ‘30s, and we cut back our line, made fewer guitars and tried to cut the cost to fit the pattern. There wasn’t much demand; we didn’t make as many guitars. The Dreadnought picked it up in the late ‘30s and then came World War II, and after that the big rush. The shortage of guitars that developed during World War II was quite important. There was a huge demand. We couldn’t keep up with it; we were two years or more behind orders during the ‘50s and the early ‘60s. All the ‘60s. And that brought us to the new factory in 1964 on a tract of land between Cherry Hill and Nazareth. In researching the title of the land, we find that it had been owned by my grandfather. Apparently he intended to build a new shop on that tract of land. Now we’re on it and the sawmill is there, and visitors are welcome. We’re not afraid of being imitated. We’ve been imitated all over the world, but the one thing that isn’t imitated is the inside workmanship. It’s there; you can feel it; and if you take a guitar apart, you can see it. The little details, the tack thickness of the braces, the pattern, the cross pattern which was developed by my great grandfather. We still use and modify for the bigger guitars. The exact angle of those braces, the exact size and shape of those little braces. The size and shape of the bridgeplate under the bridge, the size and shape of the soundhole. I say shape, and all our soundholes are round except on the cutaway model which is relatively new, where we use an oval soundhole. Anyway, the details are still being observed very faithfully. Those of you who have visited me have gotten the impression that we have only old men and there’s some truth in that. We had a layoff list of younger men who we can call back when we need them. We hope to need them quite soon. There are signs of improvement in business, and we have some new things coming out and we are very optimistic for the future. The Martin business is not over. Chris is right. The future is his.

2013 Martin CEO-7 A Martin from an Alternate Universe by T.S. Phillips

Now that you have become thoroughly steeped in the history and tradition of the C.F. Martin Company, it is only appropriate that we offer a review of a contemporary Martin instrument. We couldn’t be more excited to present the somewhat obscure Martin CEO 7 for your consideration. After a lot of searching, we acquired a new model from Musician’s Friend online for under $2,000 – a very fair price given that used models sell for more… The CEO 7 is designed by Martin’s CEO himself, Chris Martin, and it is entirely unique among all Martin models past and present. During our online research we found a single review article that was so wellwritten, thoughtful and thorough that we contacted the author and requested permission to feature it here. Thankfully, he agreed, and it is our pleasure to introduce you to T.S. Phillips and his review of the Martin CEO 7. Enjoy…

Designed by C.F. Martin IV, the new CEO-7 is a 14-fret, slope-shoulder 00 offering a unique variety of vintage guitar specs with a surprisingly affordable price tag. Specs Include: Grand Concert body size with sloped shoulders; all solid wood construction with mahogany back and sides, ebony fingerboard and bridge, Adirondack spruce top with Autumn Sunset burst finish; 1-3/4” Golden Era style modified V mahogany neck; 1/4” scalloped braces; bone nut and saddle; white ivoroid binding and matching tuner buttons; hand-fitted dovetail neck joint.

The CEO-7 is a lovely little guitar with a comfortable short-scale neck, yet with ample volume and projection. It has the versatility found in 14 frets free from the body, but with round shoulders similar to a classical design, offering some of that deep and resonant bottom end typically heard in traditional 12-fret guitars. That sloped-shoulder shape to the upper bout results in the extra sonic depth under the bass and lower mid-range. The exact dimensions are 14.764” width at the lower bout, 8.635” at the waist, and 10.589” at the upper bout. With a body length of 19.428” the overall size of the CEO-7 is somewhere between Martin’s 14-fret 000 and their 12-fret 00. It has the 4-1/8” depth shared by the 14-fret 00 and 000.

Plump and Juicy

The voice has a plump boom to it that is not exactly the same sound that comes from the standard 12-fret Martins. It is not the same voice heard from the deep body 00 design used on the Women in Music models, nor is it the same type of sound heard from the Norman Blake models, which had a 14-fret 000 body matched to a 12-fret neck. For that matter, it is not exactly like any Martin I have heard before. In fact, the CEO-7 actually has a shape and cosmetics that suggest a Gibson L-00, and yet, it still sounds like a Martin, and an impressive one at that.

When it came down to it, the whole time I was playing the guitar I kept feeling like the CEO-7 is the Golden Era Series reissue of a pre-war Martin that never existed. One might say it seems like it came from an alternate universe where Martin had been copying Gibson designs from the 1930s, rather than the other way around. But just as Gibson’s square-shoulder dreadnoughts like the Dove, Hummingbird, and Gospel sound little like a Martin D-18, the CEO-7 may have a certain trebly ring thing that reminds me of an L-00, but it also has a resonance and sustain unlike any Gibson I have heard.

Old Time Sensibilities

The vintage vibe can be seen in the narrow straight bridge and open back tuners. It can be felt in the cheeky V neck and 2-5/16” string spacing. And it can be heard in the precise fundamentals, clear chime, and open undertone that come from Adirondack spruce backed by scalloped braces, amplifying and reflecting dry, woody mahogany tone. But while it has that open “wooden box” sound typical of small, mahogany Martins, it is like someone turned up the bass. It has a certain throb that swells out from the wound strings, which isn’t usually heard from a 14-fret 00-18 or 000-18. According to Chris Martin, this new model “is a tribute to a time when flat top steel string acoustic guitar design was evolving very quickly…the market was very competitive as demand for fourteen fret neck instruments was rapidly growing. At that time the Dreadnought was not yet the dominant shape and the smaller tight-waisted models influenced by the parlor guitars of the prior century were still quite popular.”

In 1900 the 00 was the largest of Martin guitar sizes. In 30 years it went from top dog to being the choice for petite ladies and traveling troubadours who needed something small enough to stow on a train rack, or on their own back. It has remained popular with touring bluesmen and female singer-songwriters ever since.

Gibson’s L-size guitars first appeared in 1926. The L refers to the size, so that the L-00 shares the same physical dimensions with guitars designated L-0, L-1, and L-2, each with different trim and price point. The size itself comes in between Martin’s 00 and 000. And while smaller guitars have never seen modern sales numbers enjoyed by the dreadnoughts and jumbos, Mr. Martin felt it was time for a smaller model in the CEO series. And it was further decided to include a most-traditional Martin feature on a CEO for the very first time, a hand-fitted dovetail neck joint.

The Dovetail

Martin’s dovetail neck joint has a wide V-shape tenon compared to other modern neck joints, which sets tightly into the matching mortise, carved out of a solid mahogany block. The fit requires precision craftsmanship that can only be achieved by hand tools and keen expert eyes. It is so exact that a dovetail Martin can be strung up and played in perfect intonation without any glue in the joint. But most important, the wide V connection allows for considerable transference of resonant energy between the neck, neck block and the body of the guitar. You just do not have a vintage-style Martin or Gibson without it.

Every time someone claims they can’t discern the difference that comes with a dovetail neck joint, I think to myself they need to have their hearing tested. In any event, just as the ratio of balance to boom in the CEO-7 is unique among Martins, its overall voice has that fine violin purity in the trebles, along with the wavering, marrying sympathetics, and a presence glowing out around the fundamental notes that all add up to classic Martin tone. Otherwise, it shares many other features with guitars in Martin’s Vintage Series and the Golden Era series. It has 1/4” scalloped top braces identical to the 00-18V, but made from Adirondack spruce like those on the GEs. Other Golden Era specs include the cloth reinforcement strips on the mahogany sides, and a short-scale neck with 1-3/4” width at the nut, and a modified V profile carved a bit rounder, or cheekier, so it has the shape and feel of the 000-18GE and 000-42 Marquis. Overall, it is a collection of specs found on tried and tested examples of Martin’s vintage reissue fleet, but never seen in this exact combination before now.

The CEO Designs

Every so often Chris Martin designs a new limited edition. Named CEO and numbered in order of their release, these guitars combined traditional Martin elements with non-traditional features, as a way of showcasing new trends and materiel. Examples include a 12-fret dreadnought made out of solid African sapele, and a 14-fret dreadnought made from laminated Macassar ebony. Mr. Martin’s most recent ideas have reversed this trend, to offer traditional materials in designs that step outside the Martin box, or at least round off its edges.

The CEO-6 paid homage to the classic designs of Martin’s number one rival, Gibson, with a 14-fret mahogany sloped shoulder dreadnought that greatly resembled the venerable J-42, complete with a Gibson-esque sunburst top and slanted headstock logo. But aside from looks, the guitar had little to resemble a Gibson when it came to tone. Martin continued this slope-shouldered theme in a smaller body, with the release of the CEO-7.

Evolution of the Species from Divergent Ancestors

I spent a good half an hour with an early prototype of the CEO-7, several months before its debut. At the time it looked like they were making a Martin clone of the Gibson L-00. If I closed my eyes and traced the outline with my hand, I could swear it was a Gibson. However, on closer inspection, it had the shallower 4-1/8” depth of a 14-fret Martin 00, and the silhouette was slightly more symmetrical than an actual prewar L-00. But it did have a Gibsonish sunburst finish, like the CEO-6.

When I strummed a G chord, the voice said “Martin,” even more than the CEO-6 that came before it. So I was not surprised when the model appeared at the Summer NAMM show with some cosmetic makeover, combining Gibson and Martin looks into one guitar, but with all the important structural features still in place that made that early prototype so memorable. The latest version retained the black faceplate on the front of the headstock, but gone was the slanted logo. In its stead is a vintage Martin script logo used on guitars in the Authentic Series. While it still has white, Gibsony tuner buttons and pale ivoroid binding, and no purfling on the back, it has a transparent Martin toner, so the lovely Mahogany grain is seen clearly. And the jet black ebony fingerboard has the descending “long pattern” dots of a vintage Martin 00-18.

But for all its interesting looks, what makes the guitar such a success is how it feels and how it sounds, thanks to the dimensions of the neck, the combination of tonewoods, the dovetail neck joint, and that new slope shoulder body shape.

A New Voice in the Martin Choir

While the looks may be too different for some Martin fans, others may be attracted to the CEO-7 for just that reason. And while the voice may have the extra umph in the bottom end some folks always wished a small mahogany Martin could possess, others may find the voice a bit too boxy or boomy for their tastes. It is surely a different kind of Martin, but it remains more Martin than anything else.

One of the most curious aspects of this guitar is how pronounced that boom is under the three mid-range strings to the ear of the player, but how different that sounds to someone in front of the guitar. Not unlike how a dreadnought tends to sound more ferociously bassy to the player than to his audience, this CEO-7 made me question the wisdom of this new body size, at first. When I play the guitar, the D string, and to a lesser extent the G and A strings sound quite wolfy. Basically, they are perceived as unfocused and boomy, and downright distorted in my ears if I strike them too hard. But when I hear someone else playing the same instrument, viola! The mid-range sounds full yet defined. The fundamental note from the string is clear, even as it nestles in a buoyant cushion of undertone, like a dumpling in rich broth. And the lowest strings were right there with the mids. It has impressive balance, even as those low notes swell, not unlike a 12-fret dreadnought only in a smaller package. And boy, does it like open tunings! A dropped D bass string has the strong and meaty guts of a middleweight prizefighter.

It is often said that a Martin OM sounds more impressive to the listener than the player. I think that holds true for this new slope-shoulder 00 as well. It loses nothing in the punchy mids found in typical 14-fret Martin 00s. If anything, they are given a booster shot and a bassy escort, and the clear trebles are only improved by that warm, full presence humming just below them.

Tempting the Martin Faithful

After I had completed my day reviewing the new Martins slated for Summer NAMM, I enjoyed a leisurely hour sitting in the lobby of the Martin factory, playing the new CEO-7 prototype. And I must say that extra dimension under the lows really grew on me, and I relished how it was set off by those thin, pure fundamentals in the treble, with that open mahogany tone bubble spreading out around them. What made it so new and interesting, to my ear, was the unique relationship between the fundamental notes, the high harmonics over them, and the woody undertone below, with that pregnant low spot under the center of the wound strings. What made it so Martin was how each of those elements sustained after a chord, or rolled over – and over and over – during picking patterns. It just goes to show that Martin can make a guitar that looks like a Gibson, but it will never have that abrupt, reflective thunk of a low E string, or those flick-a-flick Bob Dylan/ Cat Stevens fundamental strums, or that drop off a cliff decay below the trebles. And being more of a Martin man in my aural druthers, I do not see this as a bad thing. The voice kept making me want to strum cowboy campfire songs, or move into open tunings to cry out some old timey fingerstyle blues. Seeing that I am a traditionalist, I really didn’t expect to like this guitar nearly as much as I do. Then again, there is something so traditional about the CEO-7, despite its unusual newness. But perhaps the most surprising thing about this special edition Martin remains the price. At a list price of $2,999, Martins newest mahogany 00 with the slope shoulders has more Golden Era Series features than the 00-18V, including an Adirondack spruce top, for $600 less than the 18V. And it is $1,750 less than the list price of the 000-18GE. Talk to your dealer about the real price. You may find it too good to pass up.

The model has proved so successful that dealers have a hard time keeping it in stock. But don’t worry, there is no termination date. Martin will make CEO-7s as long as people keep buying them. Not that this means you will like the CEO-7. I am sure it is not for everyone. I must confess, I have never been a sunburst kind of guy, and this Autumn Sunset burst is quite similar to many seen on 1930s Gibsons and Kalamazoos – and that is just not my cup of spruce. But if Martin ever wants to offer this exact same guitar with a plain top and a cutaway, I may be the first person in line to buy it. Then again, shaded tops have started to grow on me. And this is such a successful guitar design that I could learn to love that deep, dark fingerprint magnet called Autumn Sunset. – T.S. Phillips

T.S. Phillips is Managing Editor of One Man’s Guitar, onemanz.com/guitar, featuring unique reviews and news about fine acoustic guitars. Known as Spoon Phillips around the New York City music scene. tspguitar.com.